“Turn of the Century” Making Clear Ice Commercially

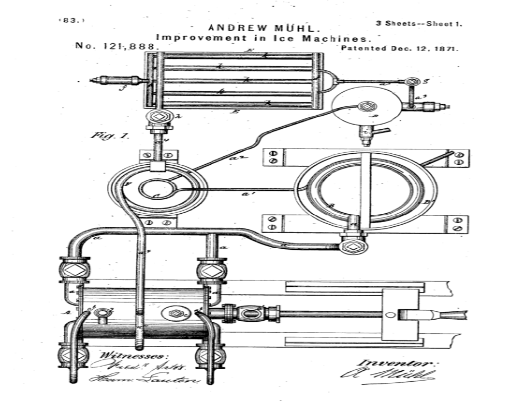

By the late 1800’s, ice making for commercial use was being perfected and developed for the growing beef, fish and food markets. During 1867 Andrew Muhl built an ice machine in Waco for the growing beef transportation industry. His patent was later contracted by the Columbus Iron Works which produced the world’s first commercial clear ice machine.

Large city populations were increasing dramatically which also increased the demand for artificial ice products. Despite this new technology the natural ice harvesting remained vital and would not decline till the turn of the century. At its peak the United States “natural ice trade” employed an estimated 90,000 people in an industry capitalized at approximately $28 million dollars per year.

During the 1920s, ice consumers purchased ice boxes lined with zinc or lead to preserve their foods. There were magical, icy cold drinks, ice box cookies, cakes, and pies that could be consumed at one’s leisure. Around 1927 Southland Ice Company started selling ice along with staples such as eggs, bread and milk at 16 storefronts in Dallas TX. This was the beginning of the modern grocery and convenience stores that started popping up on a lot of street corners.

By the late 1920s, many improvements to the early ice machines had been made by others, but they still used toxic gasses such as ammonia, methyl chloride and sulfur dioxide as refrigerants. Unfortunately, several fatal accidents were recorded due to the ice machine systems leaking methyl chloride. These dangerous refrigerants resulted in the vast research by American companies for a much safer design that could be used throughout the commercial refrigeration industry. In 1930, General Motors and Dupont formed Kinetic Chemicals to produce “Freon” which would later be the standard refrigerant for almost all consumer and industrial refrigeration products.

Recent Comments